In the bustling world of industry, where automation and efficiency reign supreme, a hidden hero emerges: the pneumatic system.

This unsung champion, powered by compressed air, propels a myriad of operations across diverse sectors.

From manufacturing giants to the high-flying aerospace industry, the pneumatic system weaves its magic, driving progress and innovation.

In this captivating journey, we’ll uncover the secrets of pneumatic systems, explore their integral components, and unveil their awe-inspiring industrial applications.

The Pneumatic Symphony: Components of a Pneumatic System

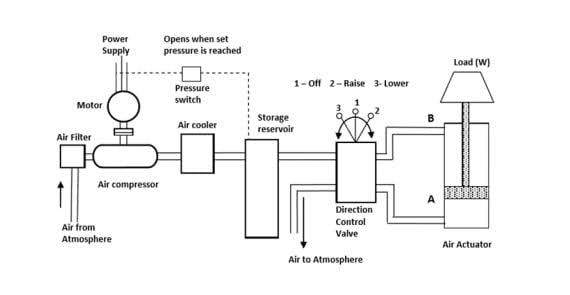

The symphony of a pneumatic system begins with its ensemble of essential components:

Compressor – The Heartbeat of Power

At the core of every pneumatic setup lies the compressor, the maestro conducting the symphony of compressed air.

This ingenious device takes in ambient air and masterfully compresses it to a harmonious high pressure, often around 90-120 psi.

With various compressor types, including reciprocating, rotary, and screw compressors, this virtuoso harmonizes power for pneumatic applications.

Reservoir/Receiver Tank – The Steady Reservoir of Energy

The reservoir tank stands tall as the reservoir of energy, ensuring a constant flow of air to the pneumatic devices.

Like a graceful dancer, it maintains a steady pressure supply, preventing pressure fluctuations that might rattle the rhythm of industrial processes.

Pneumatic Actuators – Breathing Life into Mechanical Motion

The pneumatic actuators, akin to the graceful dancers on stage, bring life to mechanical motion.

These actors come in two main forms: pneumatic cylinders and pneumatic motors.

With a burst of compressed air, pneumatic cylinders create linear motion, either single-acting, where a spring assists in the return, or double-acting, driving bidirectional movement.

Meanwhile, pneumatic motors step into the spotlight, converting compressed air’s energy into mesmerizing rotary motion.

Valves – The Conductors of Flow

Every symphony requires a conductor to direct the flow, and pneumatic systems find their maestro in pneumatic valves.

These virtuosos control the direction, pressure, and flow rate of compressed air, ensuring precision in the symphony of industrial operations.

From directional control valves to pressure and flow control valves, each takes center stage when it’s their time to shine.

Air Lines and Fittings – The Dance of Connection

The unseen dancers in this grand performance are the air lines and fittings.